Category: TPM / Continuous Improvement

-

Supply Chain

We apply best practices in the supply chain management process to ensure that it contributes synergistically, proactively, and efficiently, adding value to the business.

-

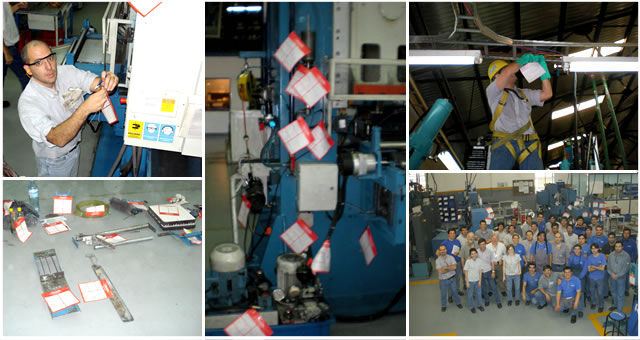

OEE (Overall Equipment Effectiveness)

In increasingly competitive markets, it is imperative to maintain accurate records of asset utilization levels. Here, we present a systematic method for monitoring the use of productive resources known as Overall Equipment Effectiveness (OEE). We believe this concept is the best indicator for measuring…

-

To take as an example: Taranto

Many of you are probably familiar with the company: Taranto is one of the most important auto parts manufacturers in Latin America and, importantly, it's Argentine-owned. In 2000 and 2005, they won the National Quality Award and proudly hold the distinction of being the first Argentine company to achieve…

-

Why make a diagnosis before putting your hands (and brain) to work?

“We already know what’s wrong. We just need someone to fix it.” The number of times consulting professionals encounter these phrases is countless. It’s like going to the doctor and saying, “I already know what’s wrong with me. I’m just here for the medicine!” It’s the same thing…

-

And if the dollar continues… Crisis!

Often, the circumstances surrounding a company are demoralizing. Whether it's due to their irrationality, the sense of injustice or powerlessness they generate, or this tendency to live on the edge of the void that we seem to cultivate, the fact remains that once again, companies find themselves facing a dilemma: how to maintain profitability or…

-

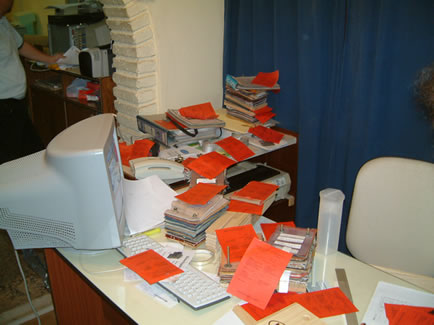

5 “S” in Offices? That’s for the factory!

We propose a test. Below are a series of questions. If you answer yes to more than 5, then you are ready to implement 5S in your office. Question Yes / No 1 Do people struggle to find pens, paper, folders, keys, etc.? 2 Are there items such as folders, documents, equipment that have no apparent owner?…