The business world is full of problems that need to be solved. The companies that survive the constant changes in the environment are precisely those that have been able to successfully resolve them. However, very few have developed the skills necessary to find the root cause of their problems. This means that similar "pains" periodically reappear, and although the "symptoms" may seem different, the organizational "disease" is the same.

What happened? The last time the pain hit, you covered it up with a fast-acting painkiller instead of trying to figure out what was causing it.

If, as a company, you're looking to create long-term solutions and generate organizational learning, then you need to apply problem analysis methodologies that ensure a continuous improvement process with the necessary immunity to ensure you don't suffer from the same problem again.

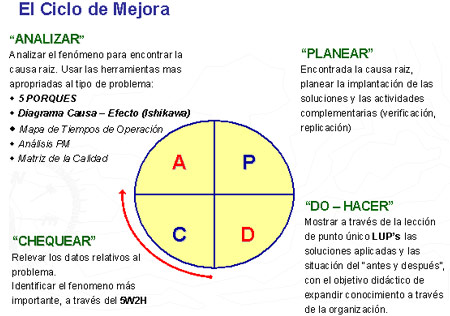

About 50 years ago, the father of modern quality management, Edward Deming, proposed a cycle of continuous improvement based on the application of four steps:

- Plan

- To do (Do)

- Check

- Act (Act)

Total Productive Maintenance (TPM), understood as an integral management system, has used for many years a modified version of the Deming Cycle to apply it to its objective of continuous improvement and loss elimination.

It basically consists of applying the same concepts but starting the cycle in a staggered manner. Instead of starting with the Planning We start with the VerificationThis means we're not designing from scratch, but rather seeking to improve, correct, or optimize a process already in place. The cycle, commonly referred to as CAPDo, consists of applying the following work sequence:

- Check

- Analyze (Act)

- Plan

- To do (Do)

Verify or “Check”

It consists of gathering data related to the problem. It involves adequately understanding the current state to have a clear idea of the deviation or "gap" in relation to the ideal or planned condition. It is not about jumping to conclusions, but rather about gathering the data associated with the problem. What do we see? What appears? What symptoms are visible?

The most important phenomenon is identified through techniques such as 5W2H

Analyze

The core of this step is analyzing the phenomenon to find the root cause. Once we have as much data as possible, we proceed to analyze it. Therefore, the goal now is to understand the reasons for the deviation: Why what happened happened. It's not about dwelling on the symptom, but rather fully understanding what caused it.

To do this, the most appropriate tools for the type of problem are used:

- 5 Whys

- Cause-Effect Diagram (Ishikawa)

- Operation Times Map

- PM Analysis

- Quality Matrix

Plan

Once the root cause is identified, we must plan the implementation of solutions with responsible parties and timelines. It's helpful here to define the most appropriate management indicators to visualize the effectiveness of the proposed actions.

Do

Finally, the time has come to implement the solution. This time, it won't be an immediate response to the stimulus that generated it, but rather the result of thoughtful action by the group of those directly involved, aimed at definitively solving the problem.

The CAPDo Cycle reinforces the concept of starting the analysis from the specific reality we want to improve (machinery, work equipment, or the company itself), what the Japanese call GEMBA. Only from there is it possible to devise actions that respond effectively and are a true solution.

Finally, the best way to capitalize on this effort is to take the time to conduct organizational learning and demonstrate the solutions implemented and the "before and after" situations through on-the-job training and coaching, with the educational goal of expanding knowledge throughout the organization.