Demand exceeding capacity as a result of boom times. Or, depending on the cycle, an urgent need to improve competitiveness in a recessionary context.

Increasingly scarce and expensive qualified personnel, attractive foreign markets, rising raw materials prices, globalized competition, and equipment with potential for further development. These are cycles we experience constantly. They are problems, they are opportunities.

Taking Charge of Your Own Reality

What will be the response to this reality that offers so many opportunities? Perhaps it's time to consider making changes that go beyond the surface. Perhaps it's time to think in the medium and long term, not just in the short term.

TPM, formerly known as Total Productive Maintenance and now better known as Total Performance Management, is increasingly popular worldwide, especially in Latin American countries. We believe this is due to the fact that more and more companies are realizing that using TPM correctly can produce amazing results. We're talking about doubling productivity and/or reducing costs by 30% or more.

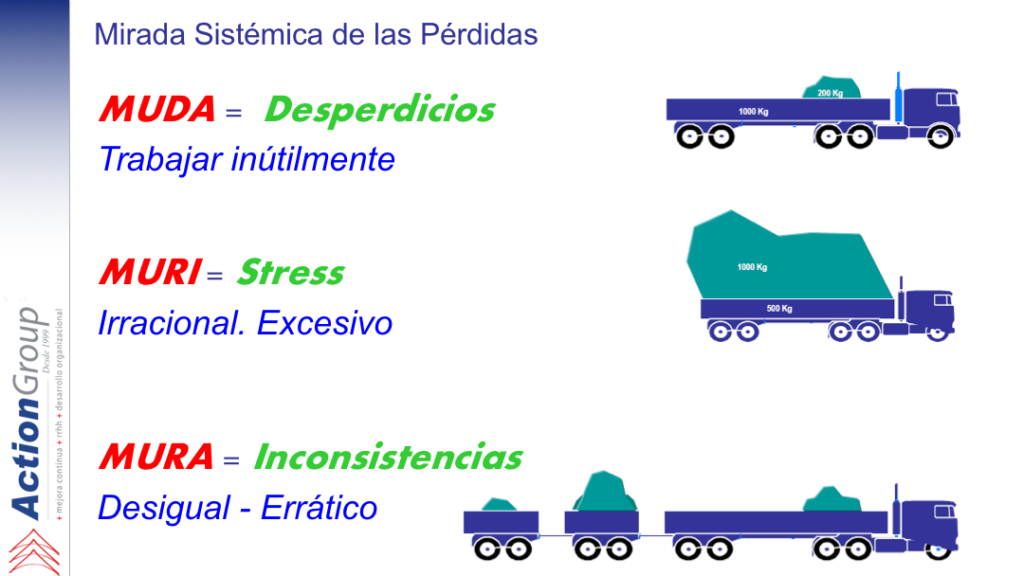

TPM is a business management method that identifies and eliminates process losses, maximizes asset utilization, and ensures the creation of high-quality products and services at competitive costs.

To achieve this, it retrains people to focus on prevention and continuous improvement, thereby increasing process capacity without additional investment.

It also acts in the value chain, reducing response time and satisfying customers, thereby strengthening the company in the market.

The effects of TPM are measured in the improvement of the results of the productive system, that is, in terms of P (Production, Productivity), Q (Quality), C (Costs), D (Internal and External Delivery), S (Safety, Health and Environment) and M (Morale and Satisfaction of people in and with the company).

TPM seeks to improve not only the factors related to results in terms of product (P, Q, C, D) but also those related to the appearance human (S and M).

Competitiveness Implementing TPM correctly

To be more specific, we can refer to some of the results achieved by plants that won the TPM Excellence Award:

1. In the production area, value-added productivity grew between 1 and 2 times.

2. Sporadic breaks were reduced from 1/10 to 1/250. 0 in Class A Equipment

3. Customer complaints related to quality decreased by 75% in 2017.

4. The cost of goods produced was reduced by 30%.

5. No delivery delays were reported.

6. A 50% reduction was achieved in work-in-process and finished goods inventories.

7. No accidents with absenteeism occurred.

8. No pollution of any kind was recorded.

9. Regarding morale, the number of suggestions generated per employee grew between five and tenfold. People choose to work there.

In short, the simplest way to understand TPM is as a highly integrative management method for existing resources that directs organizational processes to achieve business objectives. To do so, it systematically identifies and eliminates losses—that is, those that do not add value perceived by the customer.

Given the current situation in our industry, we understand that comprehensive systems like this are what allow us to capitalize on opportunities while strengthening the company to face the present and the future.

Mgter. Ing. Raúl A. Perez Verzini

TPM Instructor # 723

Japan Institute of Plan Maintenance – JIPM